Extraction Industries & Manufacturing

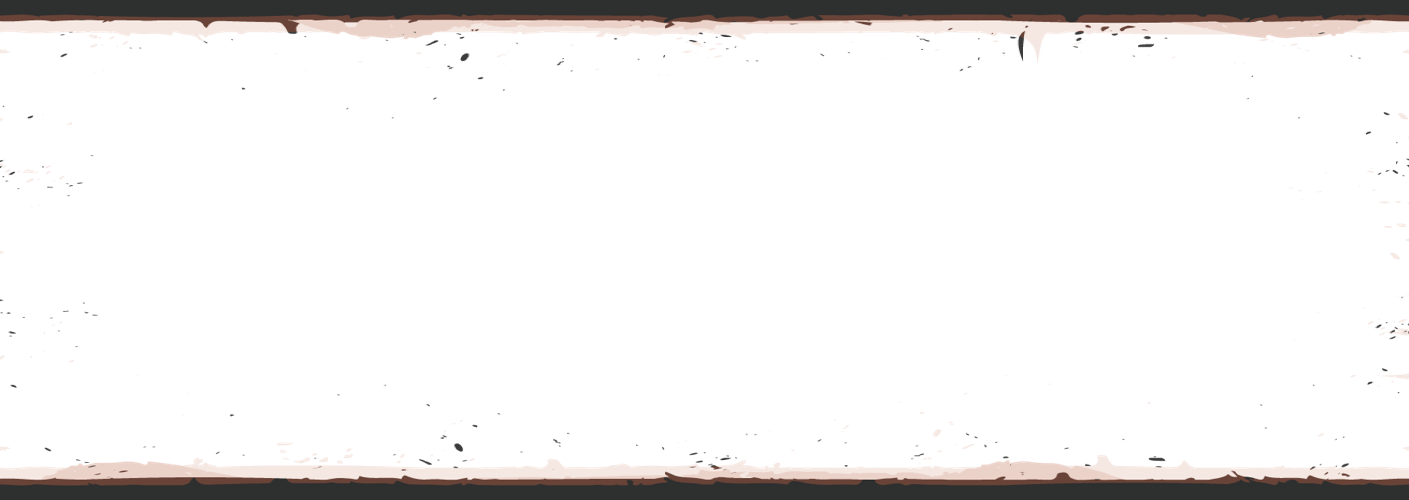

The documented history of Nitshill and nearby Hurlet gathers pace during the seventeenth century against a background of mineral extraction. By the mid-18th century, coal and other minerals were becoming important commodities and landowners and industrialists conducted extensive geological surveys to ascertain which minerals were present and at what depths. The surveys revealed that Nitshill and the neighbouring villages of Hurlet and Househillmuir stood on valuable deposits of coal, iron, aluminous schist, bituminous shale, and limestone.

Records show that small-scale coal mining had taken place in and around Hurlet since the early 17th century. Coal was extracted, sometimes by families of men, women, and children, by digging and shoring up small holes in the ground to reach shallow seams; the coal was then used in homes and industrial workshops. Keen to exploit those reserves, pioneering industrialists invested heavily to sink mineshafts, install winding gear, construct roads, and build workers’ housing, including miners’ cottages that were erected along the banks of the Levern and at Hurlet corner. By 1790, around ten thousand tons of coal were mined every year by more than two hundred colliers. As a result, Nitshill and Hurlet became an economically prosperous industrial hub for nearly two centuries.

The New Statistical Account of Scotland, 1847, reported that Nitshill and Hurlet were at that time ‘inhabited chiefly by colliers and other miners employed in the extensive works in their neighbourhood.’ However, another major employer was the Nitshill sandstone quarry, which had high quality stone that was ‘of such extent as to give employment to nearly one hundred men all the year round.’

Describing the geology, Mr Oatts, manager of the Hurlet Alum Works, reported that:

This rock has a gentle declivity from south to north, with a dip eastward. It lies over a stratum of coal 2 feet 6 inches thick. The rock is 60 feet in thickness from the coal upwards. In some parts it rises to the surface; in others, it is covered by 3 feet of earth. It contains three distinct strata of coal, besides the stratum underneath it. This coal is quite different in its nature, quality, and value, from the neighbouring Hurlet coal.

In the sandstone rock some remarkable specimens of fossil vegetable remains have been found. Two petrified trees found here are placed as curiosities near the mansion of the proprietor at Househill, the one, 10 feet high, and 5 feet round at the bottom; the other, 5 feet high, and 5 feet round at the bottom, both having the large root fissures, and protuberances equally decided and discernible with any other of the full-grown timber that now adorns the surrounding lawn.

A fossil fern procured at Levernshields is 3 feet in circumference at bottom, 1 1 feet 4 inches high,—3 feet more in length having been left behind when removing the petrifaction from the quarry. This specimen was found in the lower or bottom seam of the rock, with several others which were destroyed by the quarriers. All were found lying on a gentle declivity with their tops westwards. The natural pile and porous quality of the rock varies considerably on the different sides of each of these seams of coal, that next the bottom being the finest, that at the surface of the ground much coarser.’

It was stated that the presence of various kinds of seashells gave the name of ‘Roughmussell’ to the miners’ row on the Levern.

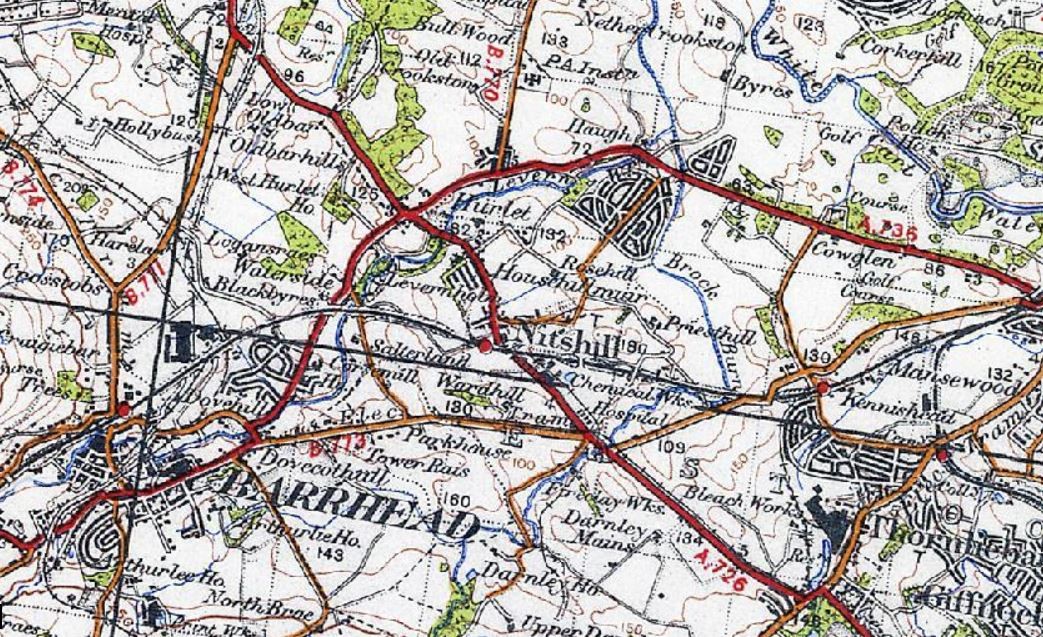

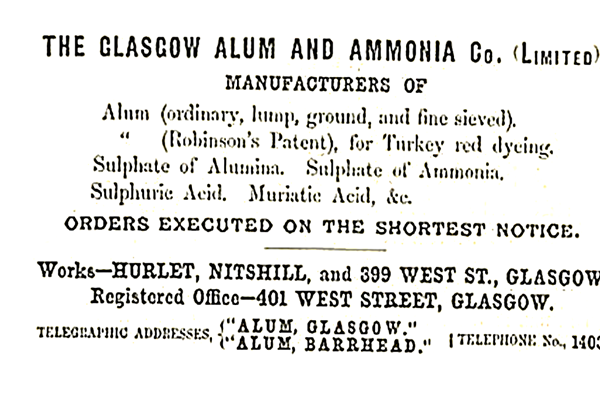

The manufacture of sulphate of iron or copperas was introduced into Scotland by Messrs Nicolson and Lightbody of Liverpool, who established their works at Hurlet in the year 1753. A similar establishment for manufacturing copperas was beg un at Nitshill in 1807, and carried on by Messrs Wilson and Sons, who, in 1820, had bought the old copperas works at Hurlet, which was then converted into an extensive alum works by Mr Wilson Junior, the managing partner of that company. The manufacture of alum was also first introduced into Scotland by Nicolson and Lightbody at their works at Hurlet in 1766 and 1767. Alum was used as a mordant in the cloth dyeing process to ensure that colours did not run out when the textiles were washed. Other uses of alum included flameproofing textiles, in baking powder, and in medicines to reduce mucus, and to stop bleeding. However, Nicolson and Lightbody’s manufacturing was process defective and was abandoned within two years. In 1797, another works was launched at Hurlet by Mr Macintosh and Mr Wilson and the manufacture of alum was successfully established and went on to produce a large and steady annual supply of alum, manufactured on correct chemical principles. Large quantities of muriate of potash and sulphate of ammonia were also manufactured due to the connection with the alum process. The muriate was extracted from kelp, and from the ammonia liquor produced at a gas works in Glasgow, and the resulting chemical was important to the numerous bleachfields and printworks of Glasgow and Paisley, Barrhead and Pollokshaws.

Transportation was central to all industrial and manufacturing with the Levern Valley. Here, the railway and the Paisley and Glasgow Canal were key for transferring raw materials and products to and from Glasgow and Paisley. The whole area in and around Nitshill and Hurlet had become hugely important to the national industrial and manufacturing economy.

In 1905, it was reported that the large limestone bed at Barrhead had long been worked as a ‘cement stone’, and brick and tile works were scattered across the Levern Valley, including one at Nitshill, where there was also an asbestos works. By the early twentieth century, the workable seams in Levern Vale were almost exhausted and the dependent chemical industries declined. As unemployment levels rose, the local population began to seek jobs elsewhere, leaving behind thatched cottages along the Levern, at Hurlet corner and at the Victoria Pithead. Battered by the elements, these houses gradually fell into ruin and the whole was reduced to desolation.

Dunlop Place and Burnside Row in Nitshill, c 1920s. The cottages to the right were a miners’ row.